EXAMAT provides ECA studies in accordance to BS7910 and API1579-1/ASME FFS-1 standards to demonstrate the integrity and safety of critical equipment or structure and whether it is sound enough to meet the service requirements for which it was intended.

To support ECA, we have excellent technic to estimate/validate the defect sizes, measured by AUT, using SALAMI SECTIONING.

BENEFITS OF ECA

METHODOLOGY

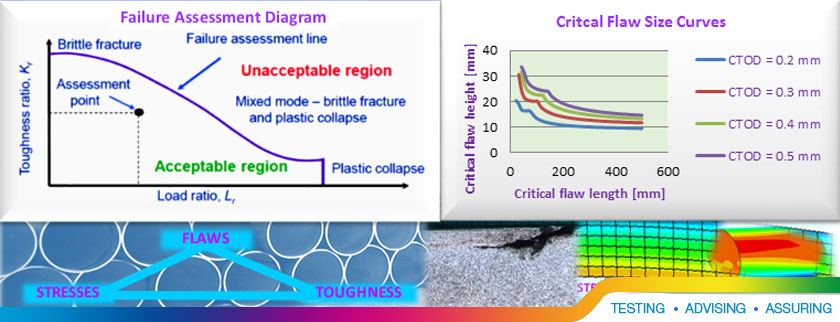

Engineering Critical Assessment (ECA) is a two-step assessment tool based on principles of fracture mechanics concepts

Simplified analyses can be carried out based on Charpy energy and maximum allowable stresses but for more realistic analysis it is necessary to use fracture-mechanics based test data (critical K, CTOD or J) instead of Charpy energy.

At any point during the life cycle of a structure (e.g. design, fabrication, installation or operation), it may be necessary to investigate whether the particular structure is fit to meet the service requirements for which it was intended, or which it will encounter in the future. Examat uses a range of assessment techniques based on principles of fracture mechanics (e.g. BS7910 and API RP 579) to provide this assessment service, which can cover a range of structures (e.g. pipelines, pressure vessels, bridges, tanks, etc.) and damage/failure mechanisms (fracture, fatigue, corrosion). Recommendations are then made as to whether the structure can be considered fit for the service, or whether repair, downrating or replacement is needed. For the flaw/imperfection which does not fall within the acceptable region as per ECA a repair may be necessary to ensure the acceptability of the linepipe for its intended applications.